November 2024 windows driver update

Microsoft recently released a driver update that make unusable some models based on the CH340 chip If your machine has stopped working, try to verify you don’t have this issue.

Common mistakes:

- Driver not installed (See point 1)

- Wrong COM or Baud setting (See point 2)

- Safety button or safety switch engaged (See point 3)

- Incompatible machine firmware or damaged firmware (See point 4)

- Microsoft driver update that make engraver unusable (See point 5)

1) Ensure COM port is recognized by the OS

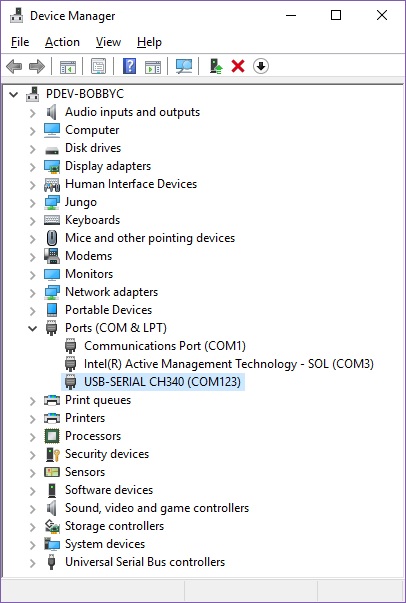

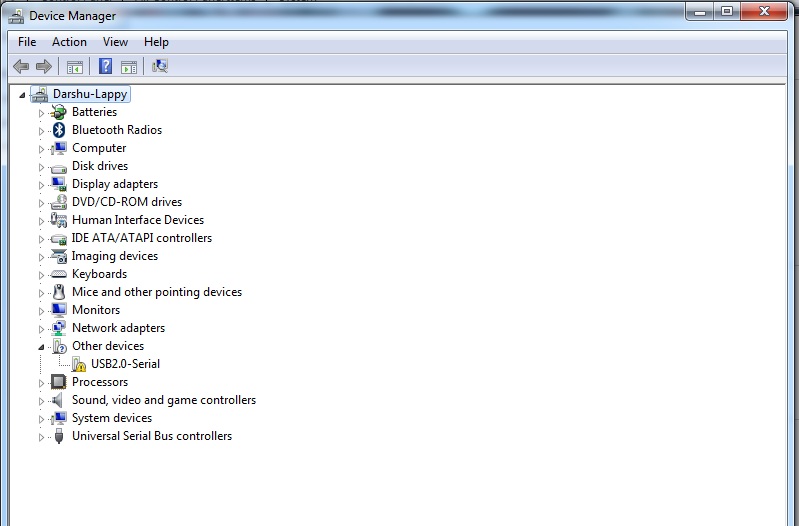

Is it necessary that your Windows OS recognize your engraver as a serial COM port once connected. Depending on the type of controller board this port may appear in the computer’s device manager with the name “USB-SERIAL CH340” or “USB Serial Device” or something else.

The name with which it appears in the device manager strictly depends on the type of machine.

If no name appears, or if a device with an error symbol appears, you probably need to install a driver. Refer to the manufacturer’s instructions to find out which driver to install.

Usually the most common controller board use the CH340 chip.

Google for “arduino CH340G” if your system does not recognize serial port.

Is it also possible to install CH340 driver with LaserGRBL from “Tools” menu:

Please note: although most of the engraver use the CH340 driver there are some models that do not use it: refer to the manufacturer’s instructions to find out which driver to install.

2) Connect with LaserGRBL

LaserGRBL constantly checks for COM ports available on the machine. The list of ports allows you to select the COM port which your control board is connected on.

This port number is the same shown near the COM port in device manager.

Please select the proper baud rate for the connection according to your machine firmware configuration. Most common speed is 115200, older controller sometime use 57600.

When connected to proper port grbl reply with “welcome message” showing Grbl firmware version “Grbl 1.1x [‘$’ for help]“.

On the bottom-right of the LaserGRBL interface you should read “Status: Idle“

If you see “Disconnected” or “Connecting” but no message come from the engraver, maybe you should change something in your COM port configuration.

Note that LaserGRBL only recognizes engraver that use the standard GRBL protocol, and cannot connect to other type of protocols (See step 4).

If you see “Status: Alarm” it means that your board is in an alarm state. The machine is connected, and this state comes from the machine: it does not indicate a LaserGRBL problem.

Usually when the machine is in Alarm status it is necessary to execute the homing procedure (if the machine is equipped with mechanical limit switches) or simply press the padlock button to acknowledge the alarm.

3) Safety button or safety switch

Newer laser models are equipped with some safety features such as a key switch and/or an emergency button. You need to make sure that the key is in the active position, and that the emergency button is not pressed.

Once pressed, the button usually remains locked in the pressed position, so it is necessary to rotate it in the direction of the arrows to unlock it.

Sometimes it is possible that this button is accidentally pressed during transport, during unboxing or assembly, during storage of the machine etc. Always check the position of the button when you have connection issues.

4) Incompatible machine firmware or damaged firmware

First of all you should know that LaserGRBL is not compatible with any laser engraver, but only with those markers that use the GRBL firmware (or a firmware compatible with it).

It’s like a spoken language, the PC and the machine must speak the same language to understand each other, and LaserGRBL speaks a language called “grbl”.

Please check this information before purchasing if you want to use it with LaserGRBL.

Even if a laser machine speaks the “grbl” language, it can happen that at a certain point its firmware (the program that runs inside the machine’s control board) becomes corrupt or damaged. This can happen due to a voltage surge, a communication issue, a defect in the machine controller itself, etc.

When this happens we often see strange characters or messages appear at startup / or when connecting to the machine. This is an example:

It’s a very uncommon case, but sometimes it can happen. You must contact the manufacturer to obtain information on how to proceed to reset the controller boar or to have a replacement.

5) Microsoft drivers update

In November 2024 Microsoft released a driver update that make unusable some models based on the CH340 chip. If your machine has stopped working, try to verify that you do not have this problem.